当前位置:主页>产品列表>造粒包衣设备>湿法高速混合造粒机

1.概述Descriptions

高速混合造粒机:高速混合mixgranulator是将需要造粒的主料和辅料按合适的比例和配方加入到搅拌器中,粉体物料和粘合剂在圆筒形容器中由底部混合桨经过高速充分混合后,成湿润软材,然后由侧置的高速粉碎桨切割成均匀的湿颗粒,从而实现了造粒的目的。也可以选配真空干燥和辅助系统设备,实现一步到位,直接获得颗粒成品。本混合设备最大的特点是快速、均匀、无死角,目前大量应用于制药、电子、电池、磁铁等要求均匀度一致性很高的场合,正逐步在一些生产线上替代常规的双螺旋混合、螺带混合以及双锥混合机。

High-speed mixing granulator: high-speed mixing wet granulator is to add the main material and auxiliary materials to be granulated to the agitator in a suitable proportion and formula. The powder material and the binder are in the bottom of the cylindrical container. After the mixing paddle is fully mixed at a high speed, it is made into a wet soft material, and then cut into uniform wet particles by a side-mounted high-speed pulverizing paddle, thereby achieving the purpose of granulation. Vacuum drying and auxiliary system equipment can also be selected to achieve one-step access to the finished product directly. The biggest feature of this mixing device is fast, uniform, and no dead angle. At present, it is widely used in applications where uniformity of uniformity is required for pharmaceuticals, electronics, batteries, magnets, etc. It is gradually replacing conventional double-spiral hybrids and snails on some production lines. With mixing and double cone mixer.

2.特点Features

本机采用卧式圆筒或圆锥形结构,用户可自由选择;

设备内表无死角,密闭状态下工作,符合 “GMP” 要求;

制粒时间短,高效节能;

制成的颗粒质地均匀,流动性好,为压片工序提供zui理想的颗粒状原料;

较传统工艺减少 25% 粘合剂,干燥时间缩短;

每批仅干混 2 分钟,造 1 ~ 4 分钟,功效比传统工艺提高 4 ~ 5 倍;

整个操作具有严格的安全保护措施;

主药与辅料差异大时,仍能达到均匀结合,无分层;

The machine adopts horizontal barrel(cone) structure. Its structure is reasonable.

The inner surface of equipment has no dead corner. It works at sealed state and conforms to the requirements of GMP.

Short granulating time, high efficiency and energy saving

The character of granule is uniform and the fluidization of granule is good. It provides ideal granule material for tablet pressing procedure.

Compare with traditional process, it can reduce 25% of binder and shorten drying time too.

Each batch needs 2 minutes to dry mixing and 1 ~ 4 minutes to granulating. Compared with traditional process, its efficiency can raise 4 ~ 5 times.

Whole operation has strict safe protective measures

3.应用Applications

GHL 型是一种在一道工序内将不同的粉状物料混合并制成颗粒的高效率设备,广泛应用于制药、食品、化工等行业。

GHL high speed mixing granulator is a high efficiency equipment that can mix different powder materials and granulate granule in one procedure. It is wide used for pharmaceutical industry, foodstuff industry and chemical industry, etc.

4.技术参数Technical Parameters

规格Specification |

10 |

50 |

150 |

200 |

250 |

300 |

400 |

600 |

|

原料容器容积 |

L |

10 |

50 |

150 |

200 |

250 |

300 |

400 |

600 |

投料量Capacity |

Kg/批kg/batch |

3 |

15 |

50 |

60 |

80 |

100 |

135 |

200 |

混合速度Mixing speed |

r.p.m |

300/600 |

200/400 |

180/270 |

180/270 |

180/270 |

140/220 |

106/155 |

80/120 |

混合功率Mixing power |

Kw |

1.2/2.2 |

4/5.5 |

6.5/8 |

9/11 |

9/11 |

13/16 |

18.5/22 |

22/30 |

切割速度Cutting speed |

r.p.m |

1500/300 |

|||||||

切割功率Cutting power |

Kw |

0.85/1.1 |

1.3/1.8 |

2.4/3 |

4.5/5.5 |

4.5/5.5 |

4.5/5.5 |

6.5/8 |

9/11 |

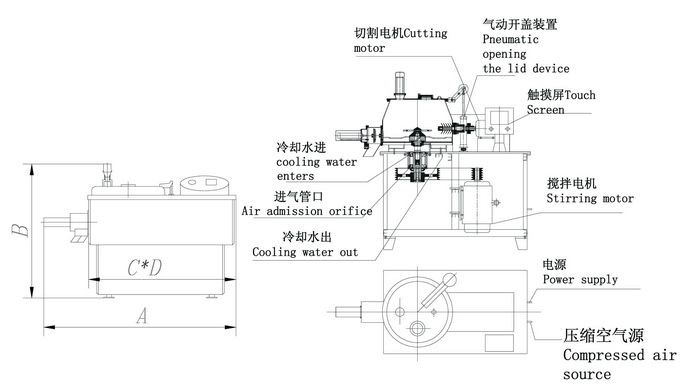

主机尺寸 |

A(mm) |

1350 |

1650 |

1750 |

2050 |

2050 |

2200 |

2350 |

2400 |

B(mm) |

1050 |

1250 |

1300 |

1400 |

1400 |

1450 |

1450 |

1550 |

|

C×D(mm) |

1000×650 |

1250×800 |

1350×800 |

1650×850 |

1650×850 |

1700×900 |

1860×1050 |

2000×1050 |

|