当前位置:主页>产品列表>干燥蒸发设备>节能干燥设备--(真空)桨叶干燥机 (通过欧盟CE & PED认证)

节能干燥设备--(真空)桨叶干燥机 (通过欧盟CE & PED认证)

Energy Saving Drying Equipment --Vacuum Paddle Dryer (CE&PED Approved)

1.概述Descriptions:

楔型空心桨叶干燥机可对膏状、颗粒状、粉状、浆状物料间接加热或冷却,可完成干燥、冷却、加热、灭菌、反应、低温煅烧等单元操作。设备中特殊的楔型搅拌传热 桨叶,具有较高的传热效率和传热面自清洁功能。

空心轴上密集排列着楔型中空桨叶,热介质经空心轴流经桨叶。单位有效容积内传热面积很大,热介质温度从-40℃到320℃,可以是水蒸汽,也可以是液体型:如热水、导热油等。间接传导加热,没有携带空气带走热量,热量均用来加热物料。热量损失仅为通过器体保温层向环境的散热。物料颗粒与楔型面的相对运动产生洗刷作用,能够洗刷掉楔型面上附着物料,使运转中一直保持着清洁的传热面。桨叶干燥机的壳体为W型,壳体内一般安排二到四根空心搅拌轴。壳体有密封端盖与上盖,防止物料粉尘外泄及收集物料溶剂蒸汽。出料口处设置一挡扳,保证料位高度,使传热面被物料覆盖而充分发挥作用。传热介质通过旋转接头,流经壳体夹套及空心搅拌轴,空心搅拌轴依据热介质的类型而具有不同的内部结构,以保证最佳的传热效果。

桨叶干燥机 can be used to dry or cool paste, granular, powder or starchy materials indirectly. It can carry out the processes of drying, cooling, heating, sterilization, reaction and low temperature calcination. The special paddle can help make sure of high heat transfer efficiency. Besides, the heat transfer surface has a self-cleaning function.

Paddles are lined densely on the hollow shaft. Heating resource will flow through the blades through the hollow shaft. The heat transfer surface may be very large in unit effective volume. Heat resource may be steam or liquids such as hot water or heat conducting oil with different temperatures from -40℃ to 320℃.Because of the indirect heat transfer, the air won't carry away any heat. Thus all the heat will be used for heating of materials. The only loss of heat is due to the heat dissipation from the insulating layer to the environment. The relative movement between the granules and the paddle surface will cause scrubbing, which can get rid of the attachments on the paddle surface. Thus there is always a clean heat transfer surface while the running of the machine. The 桨叶干燥机 has a W-shaped housing, inside which are two to four hollow stirring shafts. The seal cover and the upper cover will prevent the powders from leaking out and at the same time collect the solvent or steam .There is a baffle at the outlet, which will make sure of a high level of material layer so that the heat transfer surface will be covered with materials and play a good role. Heat transfer medium will flow through the rotating joint, then through the shell jacket and the hollow stirring shaft. In order to make sure of a good heat transfer efficiency, the hollow stirring shafts will have different inner structures according to different types of heat transfer medium.

2. 特点Features:

2.1浆叶干燥机能耗低:由于间接加热,没有大量携带空气带走热量,干燥器外壁又设置 保温层,对浆状物料,蒸发1kg水仅需1.2kg水蒸汽。

Because of the indirect heat transfer, the air won't carry away any heat. Besides, the outside shell of the dryer has a insulating layer, so it needs only 1.2kg steam to evaporate 1kg of water in slurry materials.

2.2浆叶干燥机系统造价低:单位有效容积内拥有巨大的传热面,就缩短了处理时间,设备尺寸变小。就极大地减少了建筑面积及建筑空间。

Low price:Because of the large heat transfer surface area in unit effective volume, a good drying efficiency can be achieved in a short time period and a small building area and space, using a relatively small machine.

2.3处理物料范围广:使用不同热介质,既可处理热敏性物料,又可处理需高温处理的物料。常用介质有:水蒸汽、导热油、热水、冷却水等。既可连续操作也可间歇操作,可在很多领域应用。

A large scope of applicable materials: Using different heat transfer mediums, blade dryer can be used to dry either heat- sensitive materials or materials that require high temperature. Any of the following mediums can be used for heat transfer: steam, heat conducting oil, hot water or even cooling water. So this? machine can be used in many fields either continuously or in batch.

2.4环境污染小:不使用携带空气,粉尘物料夹带很少。物料溶剂蒸发量很小,便于处理。对有污染的物料或需回收溶剂的工况,可采用闭路循环。

Environmentally friendly: No air is used or carried, and little powder material is entrained. Besides, there is a small amount of solvent evaporation, which is easy to deal with. As for materials which may cause pollution or the situation in which the solvent needs to be returned, a closed cycle can be applied.

2.5操作费用低:该设备正常操作,仅1小时/天·人。低速搅拌及合理的结构。磨损量小,维修费用很低。

Low operation cost: When the machine is operated normally, only one hour per person per day is needed. The low speed stirring way as well as the reasonable structure can make sure that there is little wear and tear and low maintenance cost.

2.6操作稳定:由于楔型浆叶特殊的压缩--膨胀搅拌作用,使物料颗粒充分与传热面接触,在轴向区间内,物料的温度、湿度、混合度梯度很小,从而保证了工艺的稳定性。

使用领域

Stable operation: As a result of the special compression - expansion stirring way of wedge-shaped blades, particle materials will be in full contact with the heat transfer sur face. In the axial range, there is a small gradient in material temperature, humidity and degree of mixing, which can thus make sure of a stable technology.

3. 适应物料Applicable materials:

3.1石化行业:聚烯烃粉体、聚碳酸酯树脂、高、低密度聚乙烯、线型低密度聚乙烯、聚缩醛颗粒、尼龙6、尼龙66、尼龙12、醋酸纤维、聚苯硫醚、丙烯基树脂、工程塑料、聚氯乙烯、聚乙烯醇、聚苯乙烯、聚丙烯、聚脂、聚甲醛、苯乙烯~丙烯腈共聚、乙烯~丙烯共聚。

Petrochemistry:Polyolefin powder, polycarbonate resin, high/Low density polyethylene, LLDPE, polyacetal particles,nylon6,nylon66,nylon12,cellulose acetate, polyphenylene sulfide, propylene-based resin, engineering plastics,PVC,PVA,polystyrene,polypropylene,polyester,POM,styrene acrylonitrile copolymer, ethylene-propylene copolymerization.

3.2环保行业:PTA污泥、电镀下水污泥、锅炉烟灰、制药厂废渣、糖厂废渣、味精厂废渣、煤灰。

Environmental protection industry: PTA sludge, electroplating sludge water, boiler soot, pharmaceutical residues, sugar residue, MSG plant residue, coal ash.

3.3饲料行业:酱油渣、骨基饲料、酒糟、食品下角料、苹果渣、橘子皮、豆粕、鸡骨饲料、鱼粉、饲料添加剂、生物渣泥

Feedstuff industry:Soy sauce residue, bone-based feed, distiller's grains, food offal, apple pomace, orange peel, soybean meal, chicken-bone feed, fish meal, feed additives, bio-slag cement.

3.4食品行业:淀粉、可可豆、玉米粒、食盐、变性淀粉、药品。

Food industry:Starch, cocoa, corn kernels, salt, modified starch, pharmaceuticals.

3.5化工行业:纯碱、氮磷钾复合肥、高岭土、膨润土、白碳黑、碳黑、磷石膏、氧化氟化钠、硝酸钙、碳酸镁、氰化钠、氢氧化铝、硫酸钡、硫酸钙、碳酸钙、染料、分子筛、皂素

Chemical industry:Soda ash, nitrogen, phosphorus and potassium compound fertilizer, kaolin, bentonite, white carbon black, carbon black, phosphogypsum, oxidation sodium, calcium nitrate, magnesium carbonate, sodium cyanide, aluminum hydroxide, barium sulfate, calcium sulfate, calcium carbonate, dyes, molecular sieve, saponin.

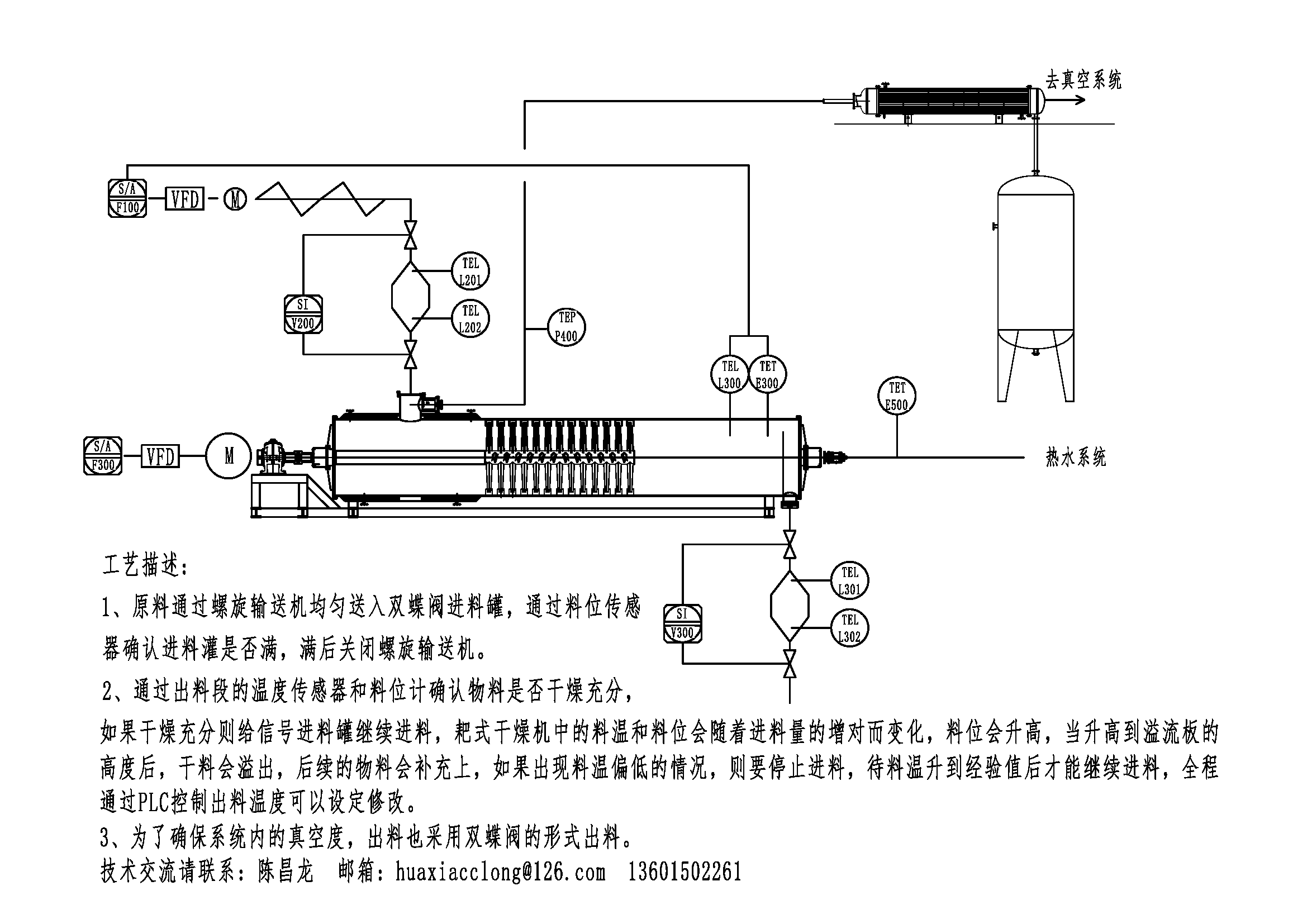

4.工艺流程图schematic diagram

5.技术参数( Technical Parameter ):

Parameter |

||||||||

型号Model |

KJG2.7 |

KJG9 |

KJG13 |

KJG18 |

KJG24 |

KJG29 |

KJG36 |

KJG41 |

传热面积 |

2.7 |

9 |

13 |

18 |

24 |

29 |

36 |

41 |

有效容积Effective volume(m3) |

0.06 |

0.32 |

0.59 |

1.09 |

1.53 |

1.85 |

2.42 |

2.8 |

转速范围Speed scope (r.p.m) |

15-30 |

10-25 |

10-25 |

10-20 |

10-20 |

10-20 |

10-20 |

10-20 |

功率Power (kw) |

2.2 |

3.8 |

5.5 |

7.5 |

11 |

11 |

15 |

15 |

器体宽Main body width A (mm) |

306 |

584 |

762 |

940 |

1118 |

1118 |

1296 |

1296 |

总宽Total width B( mm) |

736 |

841 |

1066 |

1320 |

1474 |

1474 |

1676 |

1676 |

器体长Main body length C (mm) |

1956 |

2820 |

3048 |

3328 |

3454 |

4114 |

4115 |

4724 |

总长Total length D (mm) |

2972 |

4876 |

5486 |

5918 |

6147 |

6808 |

6960 |

7570 |

进出料距Distance between material inlet and outlet E (mm) |

1752 |

2540 |

2768 |

3048 |

3150 |

3810 |

3810 |

4420 |

中心高Central height F (mm) |

380 |

380 |

534 |

610 |

762 |

762 |

915 |

915 |

总高Total height G (mm) |

762 |

838 |

1092 |

1270 |

1524 |

1524 |

1778 |

1778 |

Parameter(continuation) |

|||||||||

型号Model |

KJG48 |

KJG52 |

KJG62 |

KJG68 |

KJG73 |

KJG81 |

KJG87 |

KJG95 |

KJG110 |

换热面积Heating transfer area(m2) |

48 |

52 |

62 |

68 |

73 |

81 |

87 |

95 |

110 |

有效容积Effective volume(m3) |

3.54 |

3.96 |

4.79 |

5.21 |

5.78 |

6.43 |

7.39 |

8.07 |

9.46 |

转速范围Speed scope (r.p.m) |

10-20 |

10-20 |

10-20 |

10-20 |

5-15 |

5-15 |

5-15 |

5-15 |

5-10 |

功率Power (kw) |

30 |

30 |

45 |

45 |

55 |

55 |

75 |

75 |

95 |

器体宽Main body width A (mm) |

1474 |

1474 |

1651 |

1652 |

1828 |

1828 |

2032 |

2032 |

2210 |

总宽Total width B( mm) |

1854 |

1854 |

2134 |

2134 |

2286 |

2286 |

2438 |

2438 |

2668 |

器体长Main body length C (mm) |

4724 |

5258 |

5410 |

5842 |

5461 |

6020 |

5537 |

6124 |

6122 |

总长Total length D (mm) |

7772 |

8306 |

8865 |

9296 |

9119 |

9678 |

9119 |

9704 |

9880 |

进出口距Distance between material inlet and outlet E (mm) |

4420 |

4954 |

4953 |

5384 |

5004 |

5562 |

5080 |

5664 |

5664 |

中心高Central height F (mm) |

1066 |

1066 |

1220 |

1220 |

1220 |

1220 |

1220 |

1220 |

1220 |

总高Total height G (mm) |

2032 |

2032 |

2362 |

2362 |

2464 |

2464 |

2566 |

2566 |

2668 |