Magnetic industry ferrite granulator

Button battery powder granulator

Tungsten, cobalt, manganese granulators

Lithium iron phosphate battery granulator

Disinfectant industry granulator, dryer

Chemical industry dry powder granulator

Plastic rubber flame retardant granulator

CURRENT POSITION:HOME PAGE>PRODUCTION LIST>CRUSHER & DEAGGLOMERATION>SS Jaw Crusher(CE)

SS Jaw Crusher(CE)

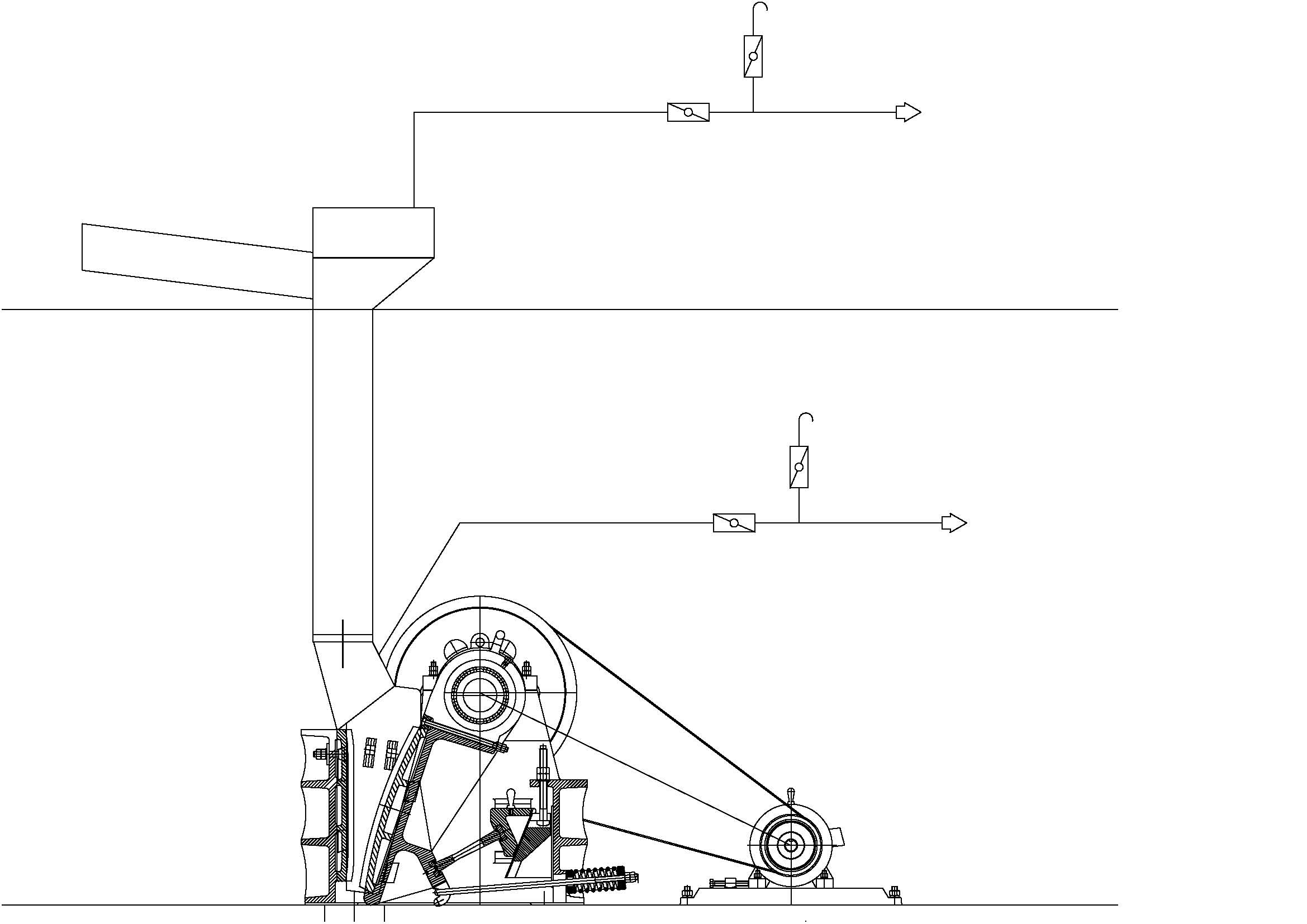

Jaw Crusher ( made of stainless steel )

( CE )

1. Description :

Stainless steel jaw crusher is grouped by the frame , fixing jaw plate , floating jaw plate, adjusting device and drive system , dust cover and other components. The big briquette material is crushed into smaller pieces between the moving plate and the fixing plate until it is smaller than the size of the discharge gap and is discharged directly from the bottom .

2. Principle :

电动机驱动皮带和皮带轮,通过偏心轴使动颚上下运动,当动颚上升时肘板和动颚间夹角变大,从而推动动颚板向定颚板靠近,此时被破碎的物料被挤压、搓、碾等多重受力而被破碎。当动颚下行时,肘板和动颚间夹角变小,动颚板在拉杆、弹簧的作用下与定颚板的间距拉大,此时被破碎的物料从破碎腔出料口排出,随着偏心轴的连续运转,动颚作周期性的往复运动,进入破碎腔的物料不断地被破碎、排出,实现连续生产。

The motor drives the belt and the belt pulley to move the movable jaw up and down through the eccentric shaft. When the movable jaw rises, the included angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw to approach the fixed jaw and the crushed material is squeezed Pressure, rub, grind and other force was broken. When moving the jaw move down, the angle between the bracket and the moving jaw becomes smaller, the moving jaw is widened from the fixed jaw under the action of the pull rod and the spring, and the broken material is discharged from the discharge port of the crushing chamber at this time, With the continuous operation of the eccentric shaft, moving jaw for periodic reciprocating movement, the material into the crushing chamber continue to be crushed, discharged, to achieve continuous production.

3.Application Scope :

It is suitable for crushing large agglomerated material into small briquettes or granules . Used for multi-level crushing of the sintered material in the metallurgical industry to reach the powdery condition , Such as silicon carbide, tungsten carbide , etc … , Feed particle size: 130-500mm, finished particle size: 15-125mm.

4.Technical parameter

Model |

Inlet size |

Feed in size(max) |

(mm)Discharge size |

Capacity( t/h) |

Power(kw) |

Measurement L×W×H(mm) |

PE150×250 |

150×250 |

130 |

15-45 |

1-4 |

5.5 |

896×745×935 |

PE250×300 |

250×300 |

150 |

15-55 |

3-6 |

7.5 |

1050×987×1000 |

PE250×400 |

250×400 |

210 |

25-60 |

5-20 |

15 |

1215×1520×1030 |

PE400×600 |

400×600 |

350 |

40-90 |

15-60 |

30 |

1650×1588×1050 |

PE500×750 |

500×750 |

425 |

50-100 |

40-110 |

45 |

1956×1918×1920 |

PE600×900 |

600×900 |

500 |

60-125 |

90-180 |

55 |

2250×2733×2280 |

PE800×900 |

800×900 |

600 |

80-140 |

100-220 |

75 |

2450×2950×2490 |

PE750×1060 |

750×1060 |

630 |

60-150 |

110-380 |

110 |

2531×2455×2783 |

PE900×1060 |

900×1060 |

700 |

100-160 |

180-380 |

110 |

2900×2657×2950 |

PE900×1200 |

900×1200 |

750 |

110-165 |

220-450 |

110-132 |

3100×2760×3260 |

PE1200×1500 |

1200×1500 |

950 |

115-195 |

250-500 |

180-220 |

3710×3446×4075 |

PE1500×1800 |

1500×1800 |

1200 |

135-225 |

350-700 |

280 |

5100×4700×4300 |

PEX150×750 |

150×750 |

120 |

10-40 |

5-16 |

15 |

1310×1118×1145 |

PEX250×750 |

250×750 |

210 |

15-50 |

15-30 |

22-30 |

1400×1751×1515 |

PEX350×750 |

350×750 |

300 |

15-50 |

18-40 |

30 |

1485×1680×1648 |

PEX250×1000 |

250×1000 |

210 |

15-60 |

15-60 |

30 |

1550×1964×1380 |

PEX250×1200 |

250×1200 |

210 |

15-60 |

20-60 |

37-45 |

1530×1946×1380 |

PEX300×1300 |

300×1300 |

250 |

25-60 |

10-65 |

55-75 |

2000×2320×1730 |

Note: customized equipment is acceptable for us .

CE & UL requirement is acceptable for us .