当前位置:主页>产品列表>干燥蒸发设备>离心喷雾干燥机(CE)

离心喷雾干燥机(CE)

Centrifugal Spray Drying Equipment

(CE Approved)

1.概述Descriptions

喷雾干燥是液体工艺成形和干燥工业中最 广泛应用的工艺。最适用于从溶液、乳液、悬浮液和可泵性糊状液体原料中生成粉状、颗粒状固体产品。因此,当成品的颗粒大小分布、残留水份含量、堆积密度和颗粒形状必须符合精确的标准时,喷雾干燥是一道十分理想的工艺。

Spray drying is the technology most widely used in the liquid technology shaping and in the drying industry.The drying technology is most suitable for producing solid powder or particle products from liquid materials,such as:solution, emulsion, suspension and pumpable paste states,For this reason,when the particle size and distribution of the final products, residual water contents, mass density and the particle shape must meet the precise standard, spray drying is one of the most desired technologies.

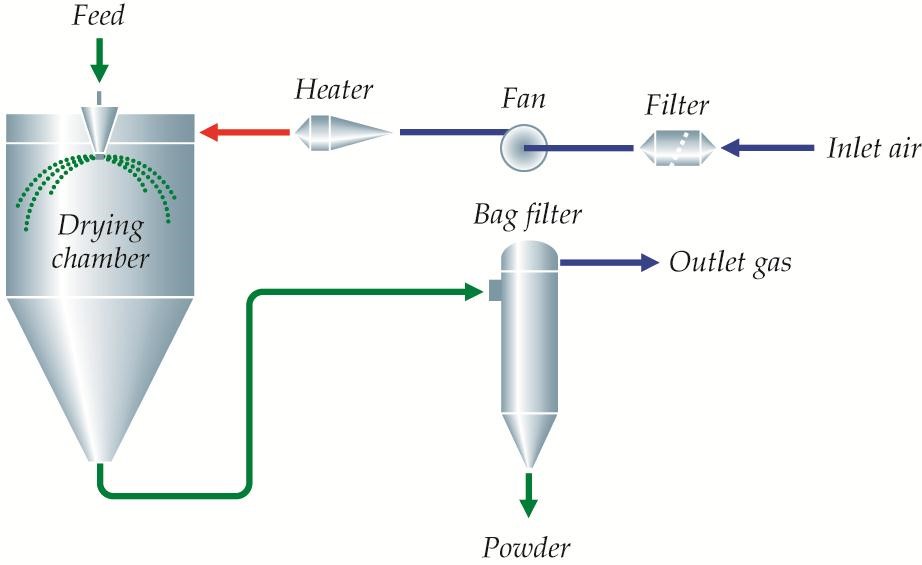

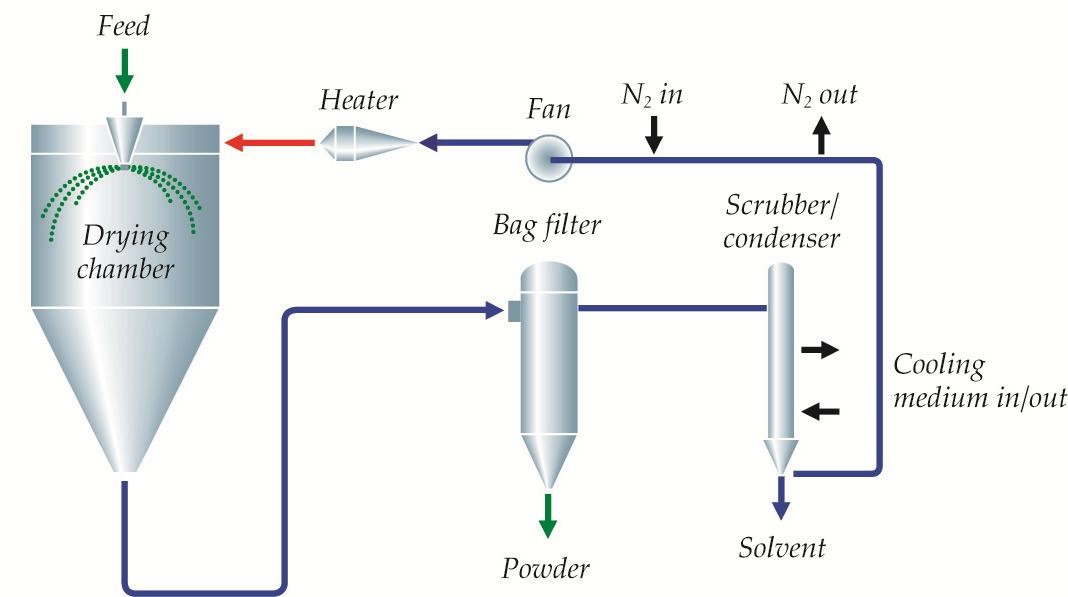

2.原理Principle

空气经过过滤和加热,进入干燥器顶部空气分配器,热空气呈螺旋状均匀地进入干燥室。料液经塔体顶部的高速离心雾化器,(旋转)喷雾成极细微的雾状液珠,与热空气并流接触,在极短的时间内可干燥为成品。成品连续地由干燥塔底部和旋风分离器中输出,废气由风机排空。

After been filtered and heated the air enters into the air distrbutor on the top of the dryer.The hot air enters into the drying room in the spiral form and uniformly. Passing through the high-speed centrifugal sprayer on the top of the tower,the material liquid will rotate and be sprayed into the extremely fine mist liquid beads.Throug the very short time of contacting the heat air,the materials can be dried into the final products.The final products will be discharged continuously from the bottom of the drying tower and from the cyclones. The waste gas will be discharged from blower.

3.应用Applications

化学工业:氟化钠(钾),碱性染料和颜料,染料中间体,复合肥,甲酸硅酸,催化剂,硫酸剂,氨基酸,白炭黑等。

塑料和树脂:AB,ABS乳液,尿酸树脂,酚醛树脂,脲醛树脂,甲醛树脂,聚乙烯,聚氯乙烯等。

食品工业:脂肪奶粉,蛋白质,可可奶粉,替代奶粉,蛋清(蛋黄),食品和植物,燕麦,鸡汁,咖啡,即时溶解茶,调味肉,蛋白质,大豆,花生蛋白,水解产物和 所以。

糖,玉米糖浆,玉米淀粉,葡萄糖,果胶,麦芽糖,山梨酸钾等

陶瓷:氧化铝,瓷砖材料,氧化镁,滑石等。

Chemical Industry: Sodium fluoride(potassium),alkaline dyestuff and pigment, dyestuff intermediate, compound fertilizer, formic silicic acid, catalyst, sulphuric acid agent, amino acid, white carbon and so on.

Plastics and resin: AB,ABS emulsion,uric acid resin,phenolic aldehyde resin,urea-formaldehyde resin,formaldehyde resin,polythene,poly-chlotoprene and etc.

Food Industry: Fatty milk powder,protein,cocoa milk powder,substitute milk powder,egg white(yolk),food and plant,oats,chicken juice,coffee,instant dissoluble tea,seasoning meat,protein,soybean,peanut protein,hydrolysate and so forth.

Sugar, corn syrup, corn starch, glucose, pectin, malt sugar, sorbic acid potassium and etc.

Ceramic: aluminium oxide,ceramic tile material,magnesium oxide,talcum and so on.

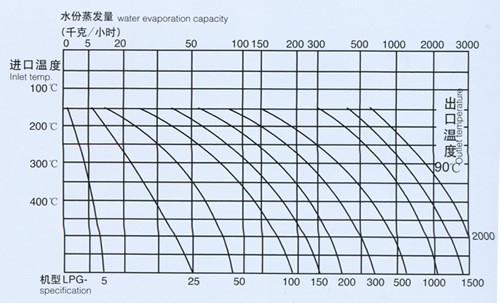

4.技术参数Technical Parameters

项目item\参数parameter\spec |

LPG |

|||||

5 |

25 |

50 |

100 |

150 |

200-2000 |

|

进风温度inlet temperature ℃ |

140-350 automatically controlled |

|||||

出风温度outlet temerature ℃ |

~80-90 |

|||||

最大水分蒸发量Max.water evaporation capacity |

5 |

25 |

50 |

100 |

150 |

200-2000 |

离心喷嘴模式centrifugal spraying nozzle transmission mode |

compressed air transmission压缩空气驱动 |

Mechanical transmission机械驱动 |

||||

转速Rotation speed rpm |

25000 |

18000 |

18000 |

18000 |

15000 |

8000-15000 |

雾化盘直径spraying desc diameter mm |

50 |

100 |

120 |

140 |

150 |

180-340 |

热源Heat supply |

Electricity |

Electricity+steam |

Electricity+steam,fuel oil and gas |

Settled by users themselves |

||

最大电加热功率Max.Electric heating power kw |

9 |

36 |

63 |

81 |

99 |

|

外形尺寸overall dimensions m |

1.8×0.93 |

3×2.7 |

3.7×3.2 |

4.6×4.2 |

5.5×4.5 |

Depends on the concrete conditions |

干粉收率Dried powder restoring rate % |

≥95 |

≥95 |

≥95 |

≥95 |

≥95 |

≥95 |

Note:For more information please contact export@huaxiadrying.com 更多信息请联系:export@huaxiadrying.com |

||||||