Magnetic industry ferrite granulator

Button battery powder granulator

Tungsten, cobalt, manganese granulators

Lithium iron phosphate battery granulator

Disinfectant industry granulator, dryer

Chemical industry dry powder granulator

Plastic rubber flame retardant granulator

CURRENT POSITION:HOME PAGE>PRODUCTION LIST>Drying & Coating>Energy Saving Drying Equipment --Vacuum Paddle Dryer (CE & PED)

Energy Saving Drying Equipment --Vacuum Paddle Dryer (CE&PED Approved)

1.Descriptions:

Paddle dryer can be used to dry or cool paste, granular, powder or starchy materials indirectly. It can carry out the processes of drying, cooling, heating, sterilization, reaction and low temperature calcination. The special paddle can help make sure of high heat transfer efficiency. Besides, the heat transfer surface has a self-cleaning function.

Paddles are lined densely on the hollow shaft. Heating resource will flow through the blades through the hollow shaft. The heat transfer surface may be very large in unit effective volume. Heat resource may be steam or liquids such as hot water or heat conducting oil with different temperatures from -40℃ to 320℃.Because of the indirect heat transfer, the air won't carry away any heat. Thus all the heat will be used for heating of materials. The only loss of heat is due to the heat dissipation from the insulating layer to the environment. The relative movement between the granules and the paddle surface will cause scrubbing, which can get rid of the attachments on the paddle surface. Thus there is always a clean heat transfer surface while the running of the machine. The paddle dryer has a W-shaped housing, inside which are two to four hollow stirring shafts. The seal cover and the upper cover will prevent the powders from leaking out and at the same time collect the solvent or steam .There is a baffle at the outlet, which will make sure of a high level of material layer so that the heat transfer surface will be covered with materials and play a good role. Heat transfer medium will flow through the rotating joint, then through the shell jacket and the hollow stirring shaft. In order to make sure of a good heat transfer efficiency, the hollow stirring shafts will have different inner structures according to different types of heat transfer medium.

2. Features:

2.1

Because of the indirect heat transfer, the air won't carry away any heat. Besides, the outside shell of the dryer has a insulating layer, so it needs only 1.2kg steam to evaporate 1kg of water in slurry materials.

2.2

Low price:Because of the large heat transfer surface area in unit effective volume, a good drying efficiency can be achieved in a short time period and a small building area and space, using a relatively small machine.

2.3

A large scope of applicable materials: Using different heat transfer mediums, blade dryer can be used to dry either heat- sensitive materials or materials that require high temperature. Any of the following mediums can be used for heat transfer: steam, heat conducting oil, hot water or even cooling water. So this? machine can be used in many fields either continuously or in batch.

2.4

Environmentally friendly: No air is used or carried, and little powder material is entrained. Besides, there is a small amount of solvent evaporation, which is easy to deal with. As for materials which may cause pollution or the situation in which the solvent needs to be returned, a closed cycle can be applied.

2.5

Low operation cost: When the machine is operated normally, only one hour per person per day is needed. The low speed stirring way as well as the reasonable structure can make sure that there is little wear and tear and low maintenance cost.

2.6

Stable operation: As a result of the special compression - expansion stirring way of wedge-shaped blades, particle materials will be in full contact with the heat transfer sur face. In the axial range, there is a small gradient in material temperature, humidity and degree of mixing, which can thus make sure of a stable technology.

3. Applicable materials:

3.1

Petrochemistry:Polyolefin powder, polycarbonate resin, high/Low density polyethylene, LLDPE, polyacetal particles,nylon6,nylon66,nylon12,cellulose acetate, polyphenylene sulfide, propylene-based resin, engineering plastics,PVC,PVA,polystyrene,polypropylene,polyester,POM,styrene acrylonitrile copolymer, ethylene-propylene copolymerization.

3.2

Environmental protection industry: PTA sludge, electroplating sludge water, boiler soot, pharmaceutical residues, sugar residue, MSG plant residue, coal ash.

3.3

Feedstuff industry:Soy sauce residue, bone-based feed, distiller's grains, food offal, apple pomace, orange peel, soybean meal, chicken-bone feed, fish meal, feed additives, bio-slag cement.

3.4

Food industry:Starch, cocoa, corn kernels, salt, modified starch, pharmaceuticals.

3.5

Chemical industry:Soda ash, nitrogen, phosphorus and potassium compound fertilizer, kaolin, bentonite, white carbon black, carbon black, phosphogypsum, oxidation sodium, calcium nitrate, magnesium carbonate, sodium cyanide, aluminum hydroxide, barium sulfate, calcium sulfate, calcium carbonate, dyes, molecular sieve, saponin.

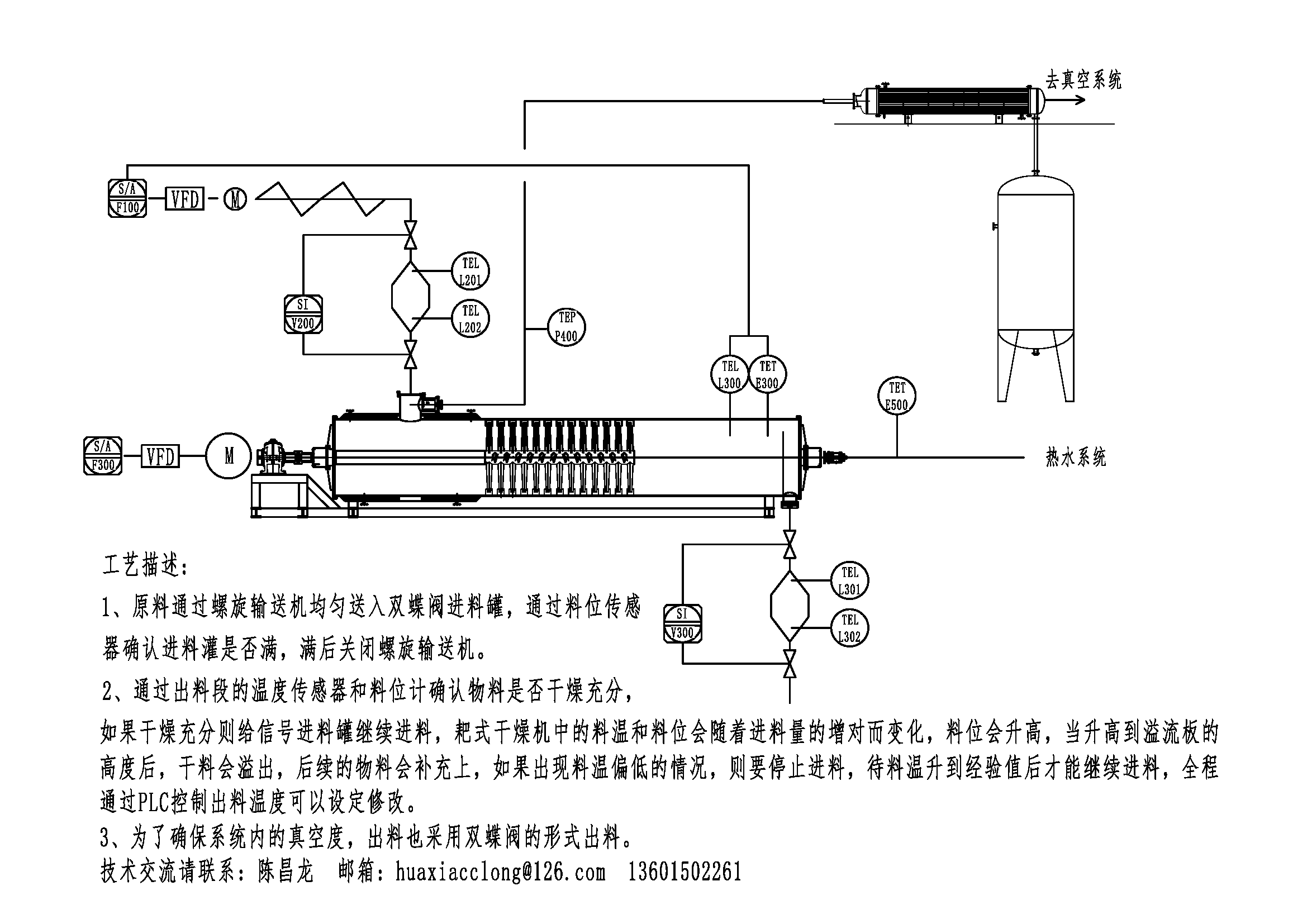

4.schematic diagram

5. Technical Parameter :

Parameter |

||||||||

Model |

KJG2.7 |

KJG9 |

KJG13 |

KJG18 |

KJG24 |

KJG29 |

KJG36 |

KJG41 |

Heating transfer area(m2) |

2.7 |

9 |

13 |

18 |

24 |

29 |

36 |

41 |

Effective volume(m3) |

0.06 |

0.32 |

0.59 |

1.09 |

1.53 |

1.85 |

2.42 |

2.8 |

Speed scope (r.p.m) |

15-30 |

10-25 |

10-25 |

10-20 |

10-20 |

10-20 |

10-20 |

10-20 |

Power (kw) |

2.2 |

3.8 |

5.5 |

7.5 |

11 |

11 |

15 |

15 |

Main body width A (mm) |

306 |

584 |

762 |

940 |

1118 |

1118 |

1296 |

1296 |

Total width B( mm) |

736 |

841 |

1066 |

1320 |

1474 |

1474 |

1676 |

1676 |

Main body length C (mm) |

1956 |

2820 |

3048 |

3328 |

3454 |

4114 |

4115 |

4724 |

Total length D (mm) |

2972 |

4876 |

5486 |

5918 |

6147 |

6808 |

6960 |

7570 |

Distance between material inlet and outlet E (mm) |

1752 |

2540 |

2768 |

3048 |

3150 |

3810 |

3810 |

4420 |

Central height F (mm) |

380 |

380 |

534 |

610 |

762 |

762 |

915 |

915 |

Total height G (mm) |

762 |

838 |

1092 |

1270 |

1524 |

1524 |

1778 |

1778 |

Parameter(continuation) |

|||||||||

Model |

KJG48 |

KJG52 |

KJG62 |

KJG68 |

KJG73 |

KJG81 |

KJG87 |

KJG95 |

KJG110 |

Heating transfer area(m2) |

48 |

52 |

62 |

68 |

73 |

81 |

87 |

95 |

110 |

Effective volume(m3) |

3.54 |

3.96 |

4.79 |

5.21 |

5.78 |

6.43 |

7.39 |

8.07 |

9.46 |

Speed scope (r.p.m) |

10-20 |

10-20 |

10-20 |

10-20 |

5-15 |

5-15 |

5-15 |

5-15 |

5-10 |

Power (kw) |

30 |

30 |

45 |

45 |

55 |

55 |

75 |

75 |

95 |

Main body width A (mm) |

1474 |

1474 |

1651 |

1652 |

1828 |

1828 |

2032 |

2032 |

2210 |

Total width B( mm) |

1854 |

1854 |

2134 |

2134 |

2286 |

2286 |

2438 |

2438 |

2668 |

Main body length C (mm) |

4724 |

5258 |

5410 |

5842 |

5461 |

6020 |

5537 |

6124 |

6122 |

Total length D (mm) |

7772 |

8306 |

8865 |

9296 |

9119 |

9678 |

9119 |

9704 |

9880 |

Distance between material inlet and outlet E (mm) |

4420 |

4954 |

4953 |

5384 |

5004 |

5562 |

5080 |

5664 |

5664 |

Central height F (mm) |

1066 |

1066 |

1220 |

1220 |

1220 |

1220 |

1220 |

1220 |

1220 |

Total height G (mm) |

2032 |

2032 |

2362 |

2362 |

2464 |

2464 |

2566 |

2566 |

2668 |