Magnetic industry ferrite granulator

Button battery powder granulator

Tungsten, cobalt, manganese granulators

Lithium iron phosphate battery granulator

Disinfectant industry granulator, dryer

Chemical industry dry powder granulator

Plastic rubber flame retardant granulator

CURRENT POSITION:HOME PAGE>PRODUCTION LIST>Drying & Coating>Energy Saving Drying Equipment --Vacuum Plate Dryer(CE & PED)

Energy Saving Drying Equipment --Vacuum Plate Dryer

(CE&PED Approved)

1.Descriptions

PLG Series Continual Plate Dryer Descriptions Plate dryer is a kind of high effective conducting and continuous drying equipment . Its unique structure and operating principle determine that it has advantages of high heat efficiency, low energy consumption,small occupying area,simple configuration,easy operating and control as well as friendly operating environment etc . It can be widely used in drying process in the fields of chemical industry. Pharmaceuticals , agricultural che micals , foods tuff , fodder , process of agricultural and sideline products etc , and is well received by various sectors in their practical usage . Now there are three big categorie s, named normal pressure , closed and vacuum styles; four sizes of 1200,1500,2200 and 3000; and three kinds of materials, namely A(carbon steel), B(stainless steel used for those all parts where materials are contacted) and C ( on the basis of B to add stainless steel materials for vapor pipes, main shaft and support, and stain -less steel linings for cylinder body and top cover). With a drying area being from 4 to 180 square metres, now we have hundreds of models of series products and various kinds of auxiliary devices available to meet requirements of drying materials for customers.

2.Principles

Wet materials are fed continuously to the first dryinglayer on the top of the dryer .They will be turned and stirred by rakes when the rake arm rotates and drop down to the outer edge of the large drying plate along the exponential helical line.On the small drying plate they will be moved to its outer edge and drop down to the outer edge of the large drying plate underneath,and will be moved inward and drop down from its central hole to the small drying plate on the next layer.Both small and large drying plates are arranged alternately so as materials can go through the whole dryer continuously.The heating media,Which could be informs of saturated steam,hot water or heat conducting oil will be led into hollow drying plates from one end to the other end of the dryer.The dried materials will drop from the last layer of the drying plate to the bottom layer of the shell body,and will be moved by rakes to the dischargeport.The moisture escapes from materials and will be removed from the moist discharge port on the top cover,or sucked out by the vacuum pump one the top cover for vacuum-type plate dryer.The dried materials discharged from the bottom layer can be packed directly.The drying capability can be raised up if equipped with supplementary devices such as finned heater,condenser for solvent in those dried paste and heat sensitive materials can be easily retrieved,and thermal decomosition and reaction can be also carried out.

3.Application

Dry, cooling, pyrolysis calcination, reaction, sublimation

(A) organic chemical products

Polyvinyl chloride resin, polytetrafluoroethylene resin, fumaric acid, anthraquinone, nitro anthraquinone, p-aminophenol, melamine, cyanuric acid, sulfanilic acid, anti-Oxygen agent 168, Naphthol As, stearate, aniline, nitrobenzene amines, dipentaerythritol, chlorinated paraffin, calcium formate, three ethylene diamine, benzene Sodium, isophthalic Formic acid, dimethyl five sulfonate, thiourea, aniline black oil-soluble dyes, acid black dyes and other organic chemical raw materials and intermediates.

(B) inorganic chemical products

Precipitated calcium carbonate, calcium carbonate, nano-scale ultra-fine calcium carbonate, magnesium carbonate, aluminum hydroxide, silica, strontium, barium carbonate, potassium carbonate, lithopone, insurance Powder, barium sulfate, potassium sulfate, microsphere catalyst, magnesium hydroxide, copper sulfate, nickel sulfate, nickel oxide, amine, sodium molybdate, sodium chloride, cryolite, red iron oxide, hydroxide Lithium, nickel hydroxide, zirconium hydroxide, calcium phosphate, sulfur and the like.

(B) the pharmaceutical, food Ampicillin, Deng salt, L-phenylglycine and intermediates, cefotaxime, ceftriaxone, dipyrone, cimetidine, vitamin B12, vitamin C, medicinal Salt, pharmaceutical aluminum hydroxide, magnesium silicate medicinal migraine, caffeine, tea, flower extract, ginkgo biloba, chocolate powder, starch, corn germ and other raw materials and pharmaceutical intermediates.

(C) feed, fertilizer

Potassium carbonate, bio fertilizer, protein feed, feed chlortetracycline, mycelium, bran, distillers, food, seeds, herbicides, cellulose, calcium hydrogen phosphate and other feed.

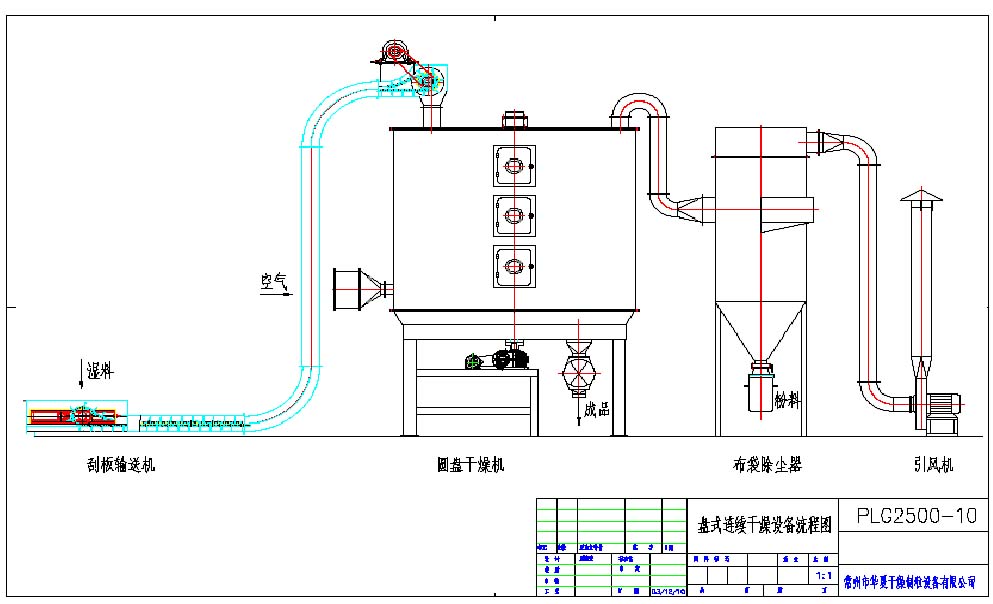

4.Flow Chart:

5.Technical parameter

| Model | Diameter mm | Height mm | Heating area m2 | Power KW |

| 1200/4 | 1850 | 2608 | 3.3 | 1.1 |

| 1200/6 | 3028 | 4.9 | ||

| 1200/8 | 3448 | 6.6 | 1.5 | |

| 1200/10 | 3868 | 8.2 | ||

| 1200/12 | 4288 | 9.9 | ||

| 1500/6 | 2100 | 3022 | 8.0 | 2.2 |

| 1500/8 | 3442 | 10.7 | ||

| 1500/10 | 3862 | 13.4 | ||

| 1500/12 | 4282 | 16.1 | 3.0 | |

| 1500/14 | 4702 | 18.8 | ||

| 1500/16 | 5122 | 21.5 | ||

| 2200/6 | 2900 | 3262 | 18.5 | 3.0 |

| 2200/8 | 3682 | 24.6 | ||

| 2200/10 | 4102 | 30.8 | ||

| 2200/12 | 4522 | 36.9 | 4.0 | |

| 2200/14 | 4942 | 43.1 | ||

| 2200/16 | 5362 | 49.3 | 5.5 |

| Model | Diameter mm | Height mm | Heating area m 2 | Power KW |

| 2200/18 | 2900 | 5782 | 55.4 | 5.5 |

| 2200/20 | 6202 | 61.6 | ||

| 2200/22 | 6622 | 67.7 | 7.5 | |

| 2200/24 | 7042 | 73.9 | ||

| 2200/26 | 7462 | 80.0 | ||

| 3000/8 | 3800 | 4050 | 48 | 11 |

| 3000/10 | 4650 | 60 | ||

| 3000/12 | 5250 | 72 | ||

| 3000/14 | 5850 | 84 | ||

| 3000/16 | 6450 | 96 | ||

| 3000/18 | 7050 | 108 | 13 | |

| 3000/20 | 7650 | 120 | ||

| 3000/22 | 8250 | 132 | ||

| 3000/24 | 8850 | 144 | ||

| 3000/26 | 9450 | 156 | 15 | |

| 3000/28 | 10050 | 168 | ||

| 3000/30 | 10650 | 180 |