Magnetic industry ferrite granulator

Button battery powder granulator

Tungsten, cobalt, manganese granulators

Lithium iron phosphate battery granulator

Disinfectant industry granulator, dryer

Chemical industry dry powder granulator

Plastic rubber flame retardant granulator

CURRENT POSITION:HOME PAGE>PRODUCTION LIST>Drying & Evapration >Double conical vacuum dryer

Energy Saving Drying Equipment --Double Conical Vacuum Dryer (According to CE&PED)

1.Descriptions

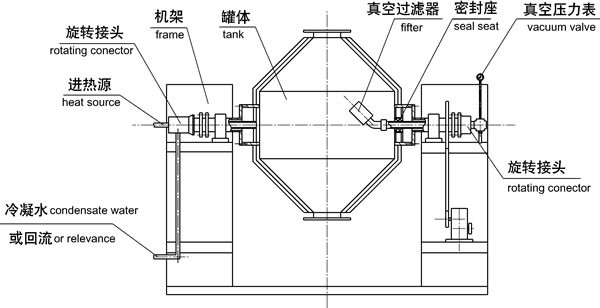

SZG Series Double Conical Vacuum Dryer is a new generation drying device developed by our factory on the basis of combining the technology of similar equipment. The whole system include double cone with jacket , gearbox ,motor ,rotary joint , instrument gauge ,vacuum system , heat source , control cabinet ,etc…

2.Principle

Raw material with moisture (solvent) feed into dryer , closed the valve ,run the motor , open the heat source valve , Let heat source (for example, low pressure steam or thermal oil or hot water) pass through the sealed jacket. The heat will be transmitted to the inner wall of cone then inner wall transmit heat to raw material , There is a temperature sensor inside the rotating cone , the working temperature can be set on the control cabinet .when the temperature of raw material raised , the moisture (solvent) will evaporate out , under the vacuum condition , the moisture (solvent ) will be removed by vacuum pump ,Under the driving of motor ,the cone is rotated slowly and the raw material inside mixed continuously .rotating time can be set on the control cabinet .

3.Applications

It is suitable for the raw materials that need to concentrate, mixed and dried at low temperature (for example, biochemistry) products in chemical, pharmaceutical and foodstuff industries. It is particularly suitable for the raw materials that are easy to be oxidized, volatilized and have light sensitivity and is toxic and not permitted to destroy its crystal in drying process.

◆ Thermal sensitive raw materials that cannot stand high temperature.

◆ Materials with solvent and dangerous gases to be collected.

◆ Materials that are dangerous and easy to oxidize.

◆ Materials that require low content of volatile residual.

◆ Materials that have special requirements for crystal shape.

4.Technical Parameters

item |

spec |

|||||||||||

name |

unit |

100 |

200 |

350 |

500 |

750 |

1000 |

1500 |

2000 |

3000 |

4000 |

5000 |

total volume |

L |

100 |

200 |

350 |

500 |

750 |

1000 |

1500 |

2000 |

3000 |

4000 |

5000 |

working volume |

L |

50 |

100 |

175 |

250 |

375 |

500 |

750 |

1000 |

1500 |

2000 |

2500 |

heating area |

m 2 |

1.16 |

1.5 |

2 |

2.63 |

3.5 |

4.61 |

5.58 |

7.5 |

10.2 |

12.1 |

14.1 |

speed |

rpm |

6 |

5 |

4 |

4 |

4 |

||||||

power |

kw |

0.75 |

1.1 |

1.5 |

1.5 |

2 |

3 |

3 |

4 |

5.5 |

7.5 |

7.5 |

rotating height |

mm |

1810 |

1910 |

2090 |

2195 |

2500 |

2665 |

2915 |

3055 |

3530 |

3800 |

4180 |

total weight |

kg |

825 |

1050 |

1350 |

1650 |

1800 |

2070 |

2250 |

3000 |

4500 |

5350 |

6000 |

design pressure inside the tank |

MPa |

-0.09~-0.096 |

||||||||||

design pressure of jacket |

MPa |

0.3 |

||||||||||

Speed adjusting motor of 0-6rpm might be chosen according to the user's requirements. The following aspects should be point out when to order:

1. The above-mentioned parameters are calculated based on material density of 0.6g/cm3. If it's over, please point out.

2. If certificate for pressure vessel is required, please point out.

3. If glass lining for interior surface is required, please point out.

If the material is explosive, or flammable, the calculation should be made according to trial result.